SIT-BOTIX

1- and 2-Arm Glue Spraying Robot for Top and Edges

The 3D market demands far greater performance than standard paint machines, and Sittex has risen to the challenge.

Pioneering Innovation – Sittex developed the world’s first Cartesian glue spraying robot with two synchronized arms, working in perfect harmony to boost productivity.

Unmatched Efficiency – Sit Botix outperforms traditional glue spraying machines, reducing execution times and maximizing output.

Cutting-Edge Vision System – Sittex was the first to integrate a camera-based scanning system, using a high-capacity silhouette acquisition process to transform data into precise trajectories within seconds. The advanced computer vision ensures unmatched quality and speed.

Precision & Durability – The gun holder axis moves with exceptional accuracy and smoothness, while the robust components ensure high application precision and an extended lifespan.

Proprietary Software – Developed entirely in-house, Sittex’s software optimizes execution speeds and accelerations, ensuring each pallet is completed well within press cycle times.

NEW SIT-TINOX

The world’s first low-cost SPRAY ROBOT for edges and top surfaces

Versatile – Perfect for applying glue or paint with precision.

Easy to use – One-side loading/unloading, requiring just one operator.

Scalable – Upgrade to an in-line system with 2 operators, 1 arm, and 2 spray guns.

Efficient filtration – Dry filtration ensures a cleaner, safer workspace.

Convenient & fast – Disposable conveyor and plug-and-play installation.

High efficiency and top quality at an unbeatable price!

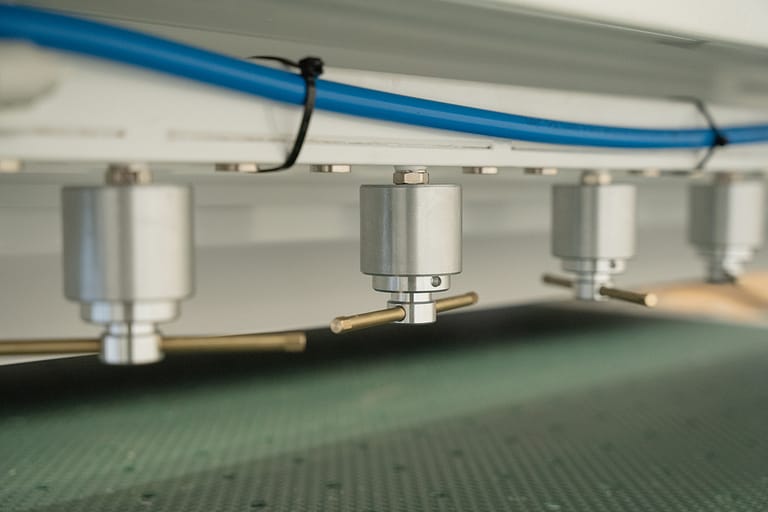

SIT-CLEAN

MDF board surface cleaning and treating machine

Sittex has developed and advanced a new, pre glue application, surface cleaning concept.

To make this possible it has been necessary to establish how the glue interfaces with the panel surface to be treated. A study which led to a novel machine of superior performance, as with all the Sittex products.

Sit clean not only cleans but prepares the panel surface for the spray application ensuring the highest end of the process quality

Sittex was the first company in the world to analyze this interaction and devise an integrated solution enhancing the final quality and adding value to the product.

Today further improved thanks to the inclination of the treatment tools.

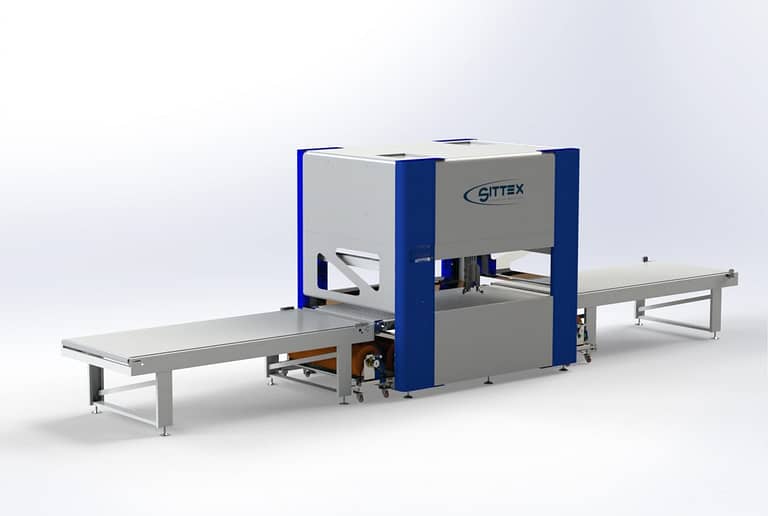

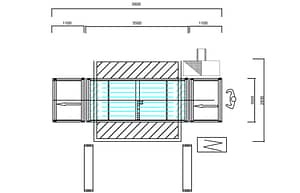

SIT-ONE

One arm spray machine with dry filtration and conveyor

Sit one is a one-arm spray machine made of a solid welded frame in order to ensure maximum stability during even the heaviest use.

Created for spraying glues of various types and quantities. Both at high and low pressure.

The internal volume and filtering surface concept optimizes the spray efficiency as well as internal cleanliness.

The careful study of these proportions grants first and foremost a consistent quality throughout the working hours and secondly keeps the machine free of contamination problems allowing minimal maintenance both during and at the end of the shift.

The use of specific transport disposal material guarantees minimal running costs and coil changes per shift.

Useful working width: 1300 mm.

SIT-ERS

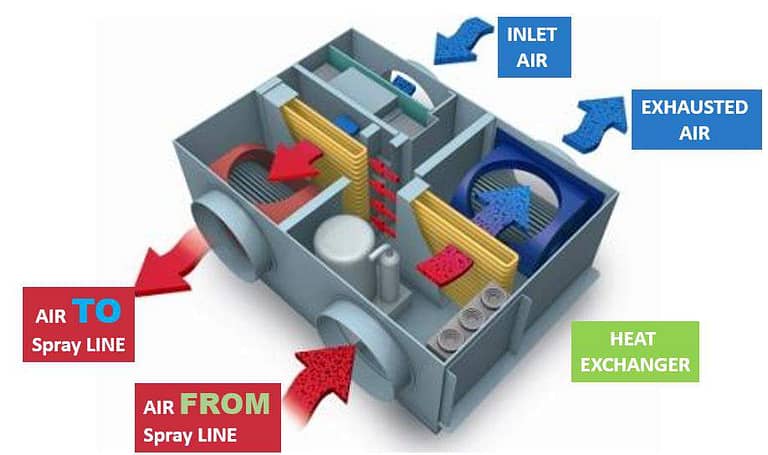

Sittex has developed pre-press systems for the recovery of energy

otherwise wasted and lost to the external environment.

This, especially in the wintertime and in cold areas, makes it possible to reduce up to 10 times the energy required to treat the external air introduced into the pre-press line.

SIT-MIX

The only pre-press machine in the world capable to precisely mixing, on demand and continuously PU glues used in this sector, with only 3-5% hardener

Allows the continuous control and logging of the product production time.

Reduces the waste glue as is in demand.

Washing and cleaning is automatic with waste collection.

SIT JET OVEN

Is a high air speed in line oven for the glue spray

With this oven is possible to dry the applied glue both on edges and on top in few minutes.

The machine operation is guaranteed from the lifting sturdy motorgears of the pieces tray system.

According to the oven length, to the line/press speed the drying time may vary from minimum 1 min to 3-4 (as average). The inner temperature is adjusted by means of a air make up unit with water heating exchanger. The recirculation fans grants the highest air speed an uniformity for the glue drying.

SIT-FLEX OVEN

FIFO tray oven for glue dryng

With this oven it is possible to dry the glue applied both on the edges and on the surface in a few minutes.

Tray lifting movements are ensured by the cardan transmission which, with robust reduction gears, activates the lifting of the tray supporting the pieces. Depending on the length of the trays (3500-7500mm),

the number of trays (4-5 or 6) and the application/press cycle, the drying time varies from a minimum of 6-8 minutes to about 12-15 on average.

The internal temperature is adjusted by means of a water exchanger heating group.

The booster fans guarantee excellent uniformity and quantity of air for glue drying.

The machine works in FIFO logic.

As an alternative to heating, the machine can be equipped with a recirculation dehumidification system. This allows for better drying performance and significant energy savings. Dehumidification, compared to high temperature ovens, increases the final quality of the pressed product, both in terms of adhesion and surface.

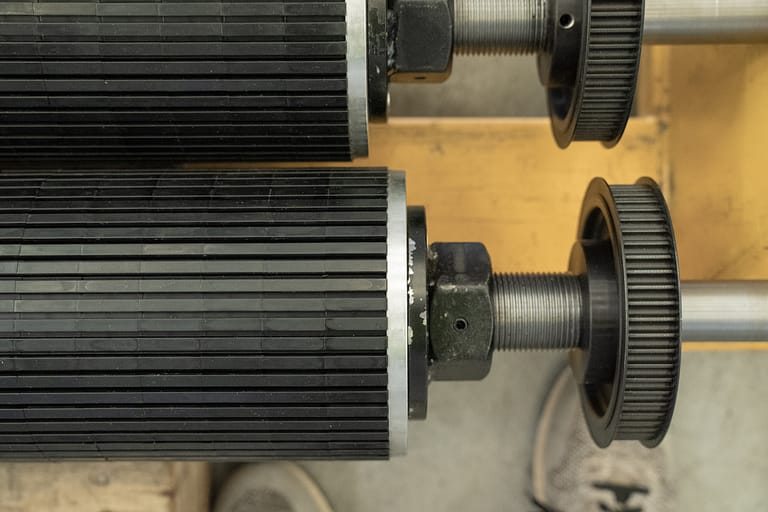

SIT DNB

Pre-press surface smoothing machine

After spraying and drying the glue on the panels, the surface is not smooth.

The solution of many companies is to do manual sanding on the press tray.

Sittex has introduced the first surface glue smoothing machine to ensure the best surface result without abrading the glued surface.

A clean and dust free operation done prior to entering the press.